Motivation & Objectives

In the past 40 years, many research efforts have been directed towards developing life-cycle management paradigms for engineering structures that can be applied online (limiting downtime) and in an automated fashion (limiting the need for costly man hours). Aside from the implementation of such frameworks in the industry of rotating machinery, the collection of these online frameworks falls under the field of Structural Health Monitoring (SHM). When it comes to active-sensing guided wave SHM, one of the major challenges the SHM community is facing today is related to enabling accurate and robust damage detection and quantification under stochastic, spatially- and time-varying operational and environmental conditions the --oftentimes limited-- available information. In addition, the currently utilized techniques suffer from low damage/damage evolution sensitivity, need for user-defined thresholds, and non-uniform response across a sensor network, amongst others.

Main Contributions

The major aim of this work is the development of a robust, accurate, and data-intelligent, probabilistic/statistical damage detection and quantification framework for active-sensing guided-wave SHM. In principle, given an active-sensing guided-wave SHM network, the following are the main contributions of this work:

- Detecting damage within a stochastic, spatially- and time-varying environment.

- Selecting data sets carrying most information about damage size.

- Developing a quantification model robust to uncertainties using only those data sets.

- Extracting detection and quantification confidence intervals for informed decision-making.

Method of Approach

In order to attain these goals, a unified probabilistic SHM framework is proposed integrating stochastic time series representations and Gaussian process regression models (GPRMs) for damage detection and quantification.

- Development of data-intelligent SHM models for low data availability scenarios.

- Enabling probability-educated decision-making via defining theoretical and experimental confidence intervals for SHM.

- Complete parametrization of damage location and size for guided-wave SHM with a single model.

- Expansion of uncertainty modeling from component-based to fleet-based.

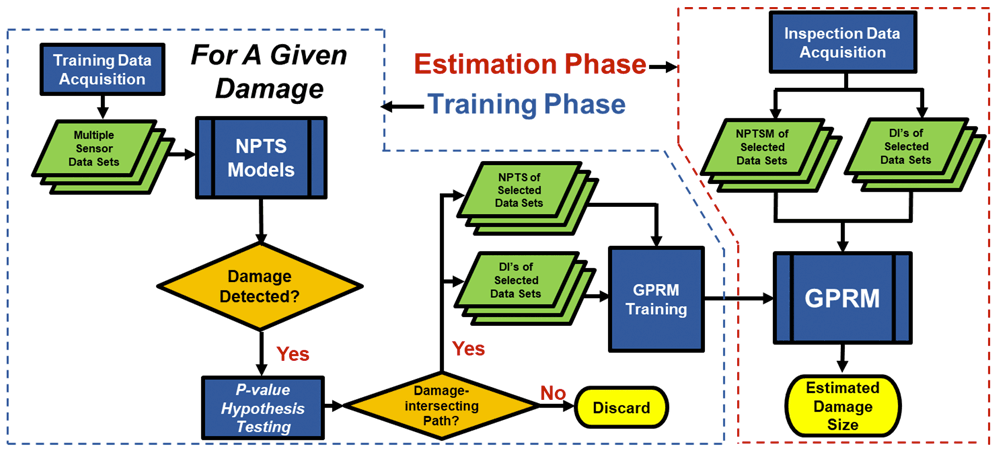

Figure 1 shows one application of such a framework using non-parametric time series (NP-TS) representations and GPRMs. This framework was also applied in such a way where the GPRMs are integrated with parametric time series instead of non-parametric ones.

Indicative Results

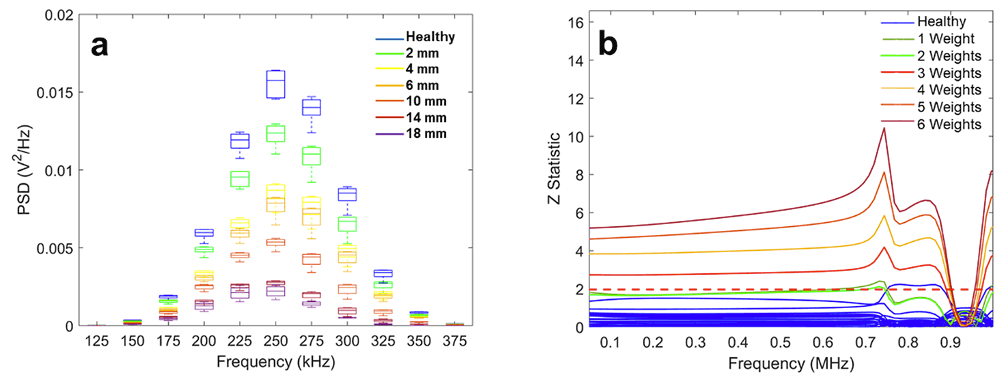

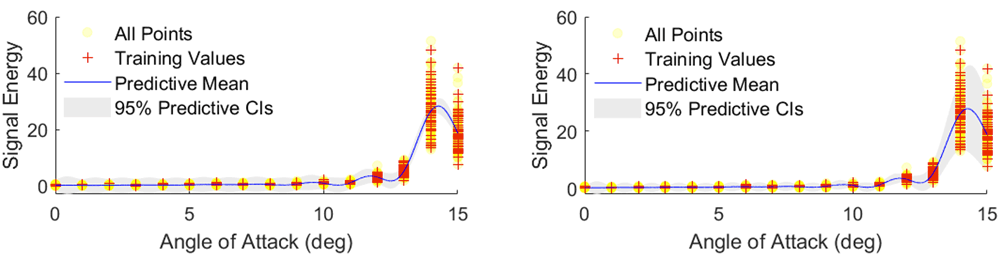

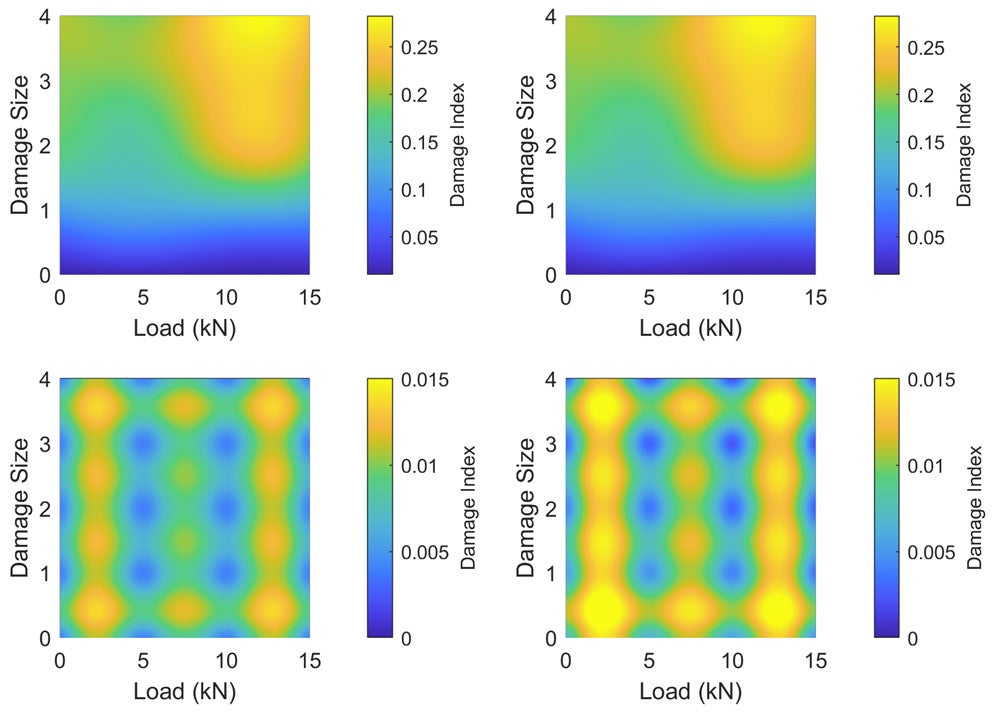

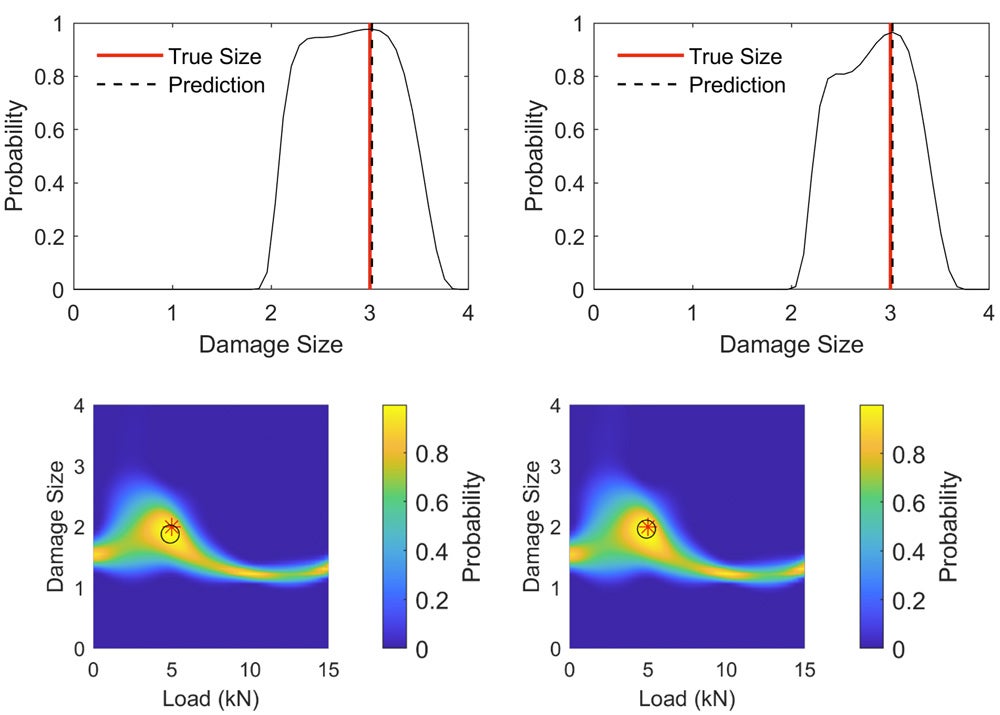

Figure 2s shows indicative NP-TS representations for statistical signal path selection, which depending on the trend versus damage, can give insights on which actuator-sensor paths are damage-intersecting, and which are not. Figure 2b shows indicative NP-TS representations used for damage detection. For state identification/quantification, publicly-available homoscedastic and heteroscedastic GPRM algorithms were used to capture the trends in the training data and noise. Figure 3 shows indicative GPRM predictive means and variances for the variation of signal energies from sensors attached to a wing in a wind tunnel with angles of attack and airspeeds. Figure 4 shows GPRMs trained with two-dimensional data modelling the effect of damage size and load on the damage index values in an Al plate. Figure 5 shows indicative damage size prediction probabilities at a known load, and indicative 2-state prediction probabilities.